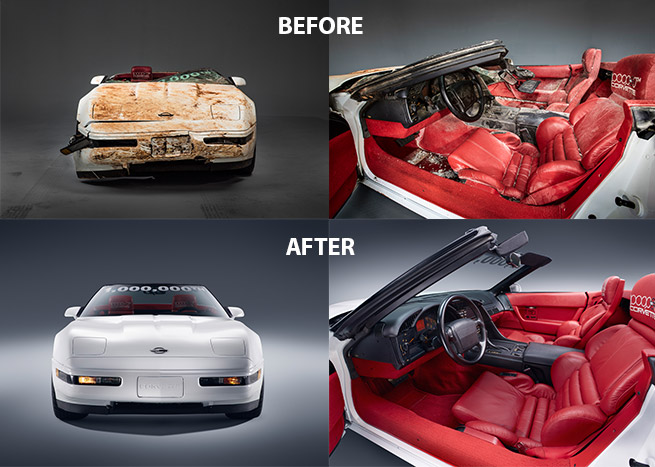

After more than four months and 1,200 man-hours of painstaking craftsmanship, restoration of the milestone 1 millionth Corvette – a white 1992 convertible – is complete.

After more than four months and 1,200 man-hours of painstaking craftsmanship, restoration of the milestone 1 millionth Corvette – a white 1992 convertible – is complete.

It was unveiled today at the National Corvette Museum, where it returns as part of the permanent exhibit. The car was damaged on Feb. 12, 2014, when it and seven other rare Corvettes tumbled into a sinkhole that opened beneath the museum’s Skydome area.

Chevrolet pledged to restore it.

“We felt it was important to restore this extremely significant car in Corvette’s long, storied history,” said Mark Reuss, General Motors executive vice president, Global Product Development, Purchasing and Supply Chain. “When we disassembled it, we found that each employee involved in building it had signed a part of the car, which was fantastic and moving to see. It brought the history to life, and reinforced the importance of the project.”

After recovery from the sinkhole, the 1 millionth Corvette was moved from the museum to the Design Center on GM’s Technical Center campus in Warren, Mich., for restoration. Approximately 30 craftspeople and technicians from GM Design’s Mechanical Assembly group, along with GM Service Operations, took on the project. Mechanical Assembly and the Fabrication Shops at GM Design build concept vehicles and maintain GM’s historic vehicle collection.

“As the one and only 1 millionth Corvette, its preservation was important to us as the designers of the vehicle – and as Corvette enthusiasts,” said Ed Welburn, vice president of GM Global Design. “The damage was significant in many ways; however we have one of the most highly skilled specialty shops and team of people in the industry, so they were fully prepared to take on the challenge.”

Despite extensive damage, the team, represented by UAW locals 160 and 1869, vowed to preserve and repair as many original components as possible – a decision that involved posterity as much as history. That’s because under the skin, the 1 millionth Corvette carried all those signatures from the Bowling Green Assembly workers who built the car.

Only two signed components couldn’t be saved, so the team had the autographs scanned, reproduced as transfers and placed on the replacement parts.

“We went to great lengths to preserve every autograph,” said David Bolognino, director of GM Global Design Fabrication Operations. “In the end, we saved every one of them, which was an unexpected and important element to the restoration.”

One component with a single signature from Bowling Green Assembly employee Angela Lamb was too damaged to save or even accurately scan for her autograph. Chevrolet worked with the National Corvette Museum to secure a new signature from Lamb on the replacement part, so the 1-millionth Corvette will be historically accurate down to the last signature.

Among the parts replaced were the hood, front fascia and the lower panels between the front wheels and doors, as well as a number of ancillary supporting components under the hood. The replacements came from a vehicle of the same vintage and color, ensuring authenticity of the parts and materials involved with the restoration.

A few other components, such as the rear fascia and front exhaust system, would have probably been replaced in almost any other restoration project, but the team repaired them because they were also covered in signatures.

Source: Chevrolet